Areas of Application and Advantages

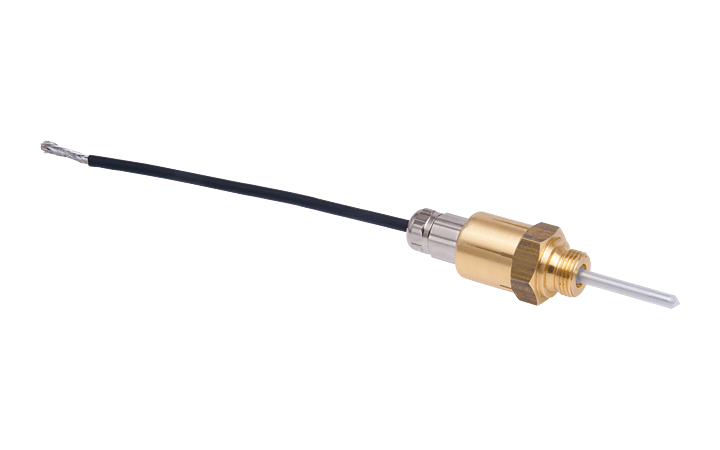

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit.

Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored.

Due to their rugged design, high IP protection classes and a working temperature range from -40 °C to +125 °C (-40 °F to +257 °F) the BEDIA monitoring sensors are primarily used in the following areas:

- Railway

- Engines

- Hydraulic power-train control systems

Wherever pressure switches or temperature sensors are today used as level monitoring elements, this sensor offers the advantage of indicating a critical condition far earlier:

Temperature sensors frequently react too late, because the medium to be monitored is no longer present. The rise in temperature is not passed on to the pick-up sensor. Pressure switches do not indicate low oil until there is a total shortage of oil and thus too late to protect the engine. The level sensor already indicates a critical filling level.

BEDIA level monitoring sensors differ from float-type switches in their compact design and their resistance to vibration:

Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible.

Operating Principle

The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage.

Types of Media

The level monitoring sensors are designed for two different media types:

- For electrically conductive liquid media

with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) - For electrically non-conductive liquid media

with relative permittivity within a range of εr 1.8 … 6 (engine oil, fuels, hydraulic oil)

Available Output Versions

The following output versions are available:

- positive switching

- negative switching

- analog output

- proportional analog output

Function Control Time

After the supply voltage is applied (e. g. ignition being switched on), the output is activated for the function control time, thus signalling operational readiness. If this signal does not appear, the sensor should be checked. The default function control time is 2 seconds. This self-monitoring makes it possible to check the level monitoring sensors from a central point for their operational readiness as well as for cable breaks. Especially in intricate, ramified systems, such as ships, checking conventional level switches may be very difficult.

Other function control times are available upon request.

Fault Indication Delay Time

To avoid indication errors when the swashing surface produces short fluctuations of the liquid level, the output signal is delayed with the standard fault indication delay time of seven seconds.

Other indication delay times are available upon request.

Mounting Position

BEDIA level monitoring sensors may be installed in any position.

For properly function the level sensors should be mounted in a calm area of the tank, otherwise a sensor with a fault indication delay should be used. This point is usually applicable for installation in gearboxes or for direct installation in engine oil pans during operation. In such cases, the measurement is only possible at engine shutdown.

It is mandatory to mount the sensor with a minimum distance of 7 mm to the wall.